DDM’s delivers precision investment castings of complex engineered components with the convenience of 3D printed ceramic shell molds.

DDM Digital Foundry™

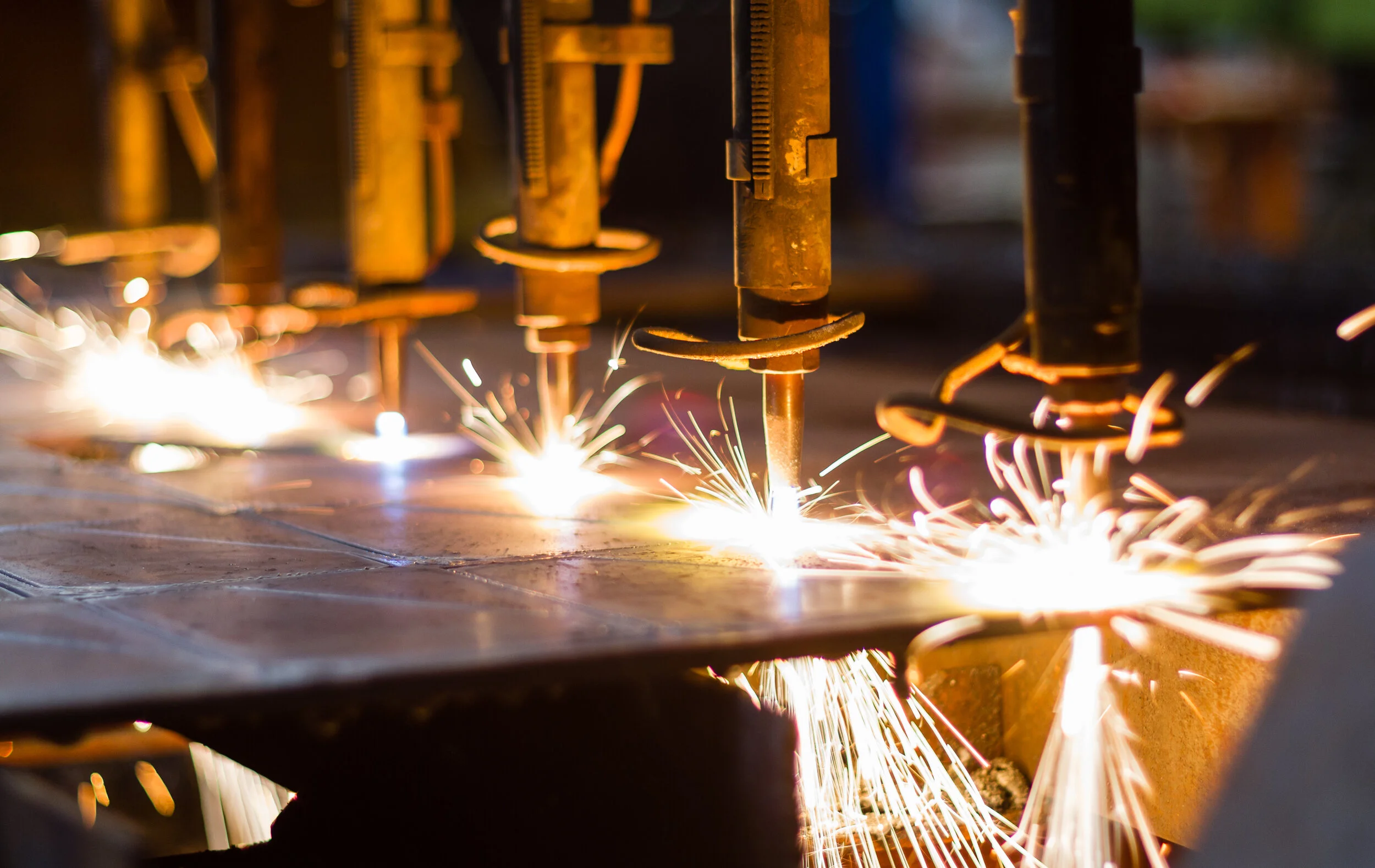

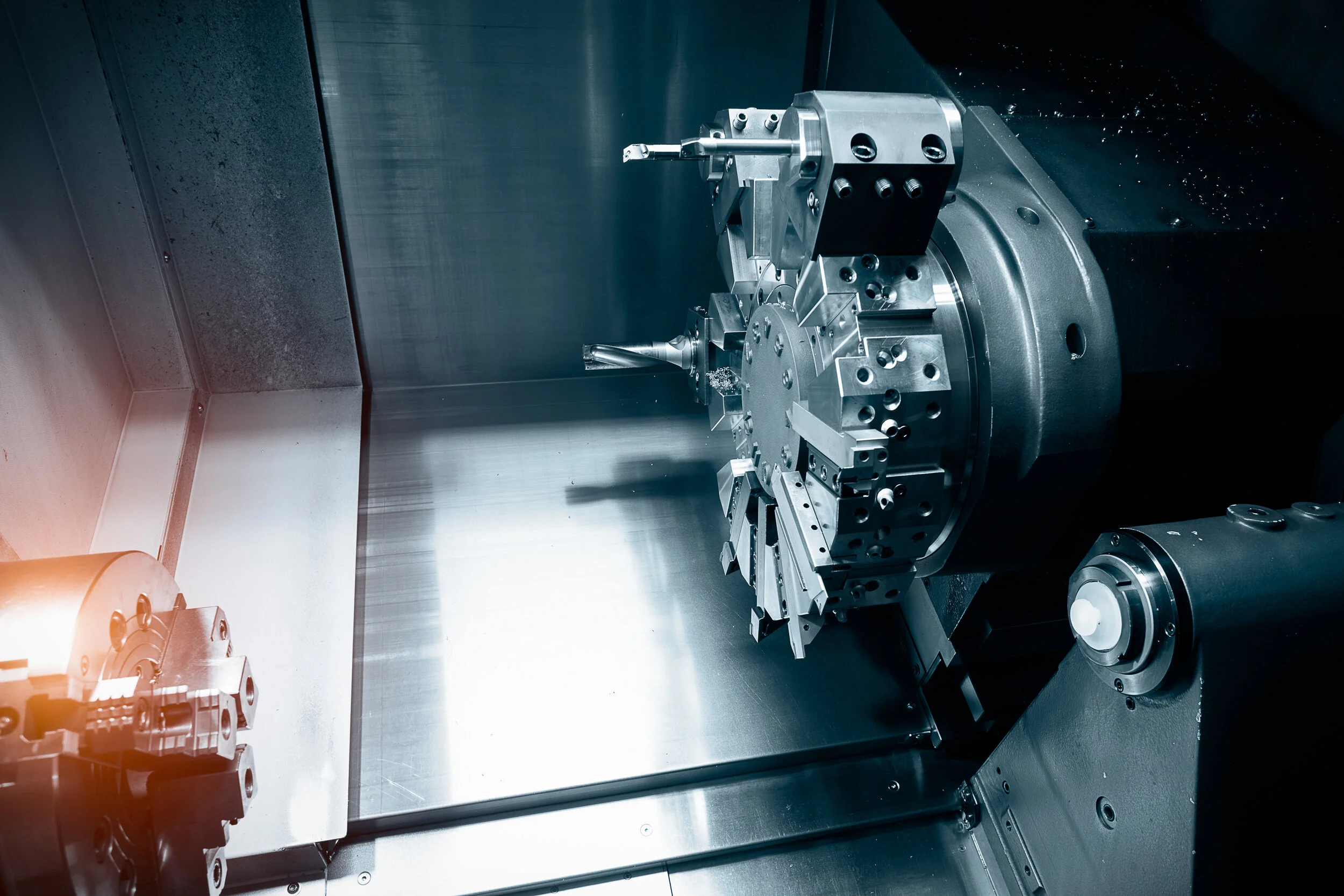

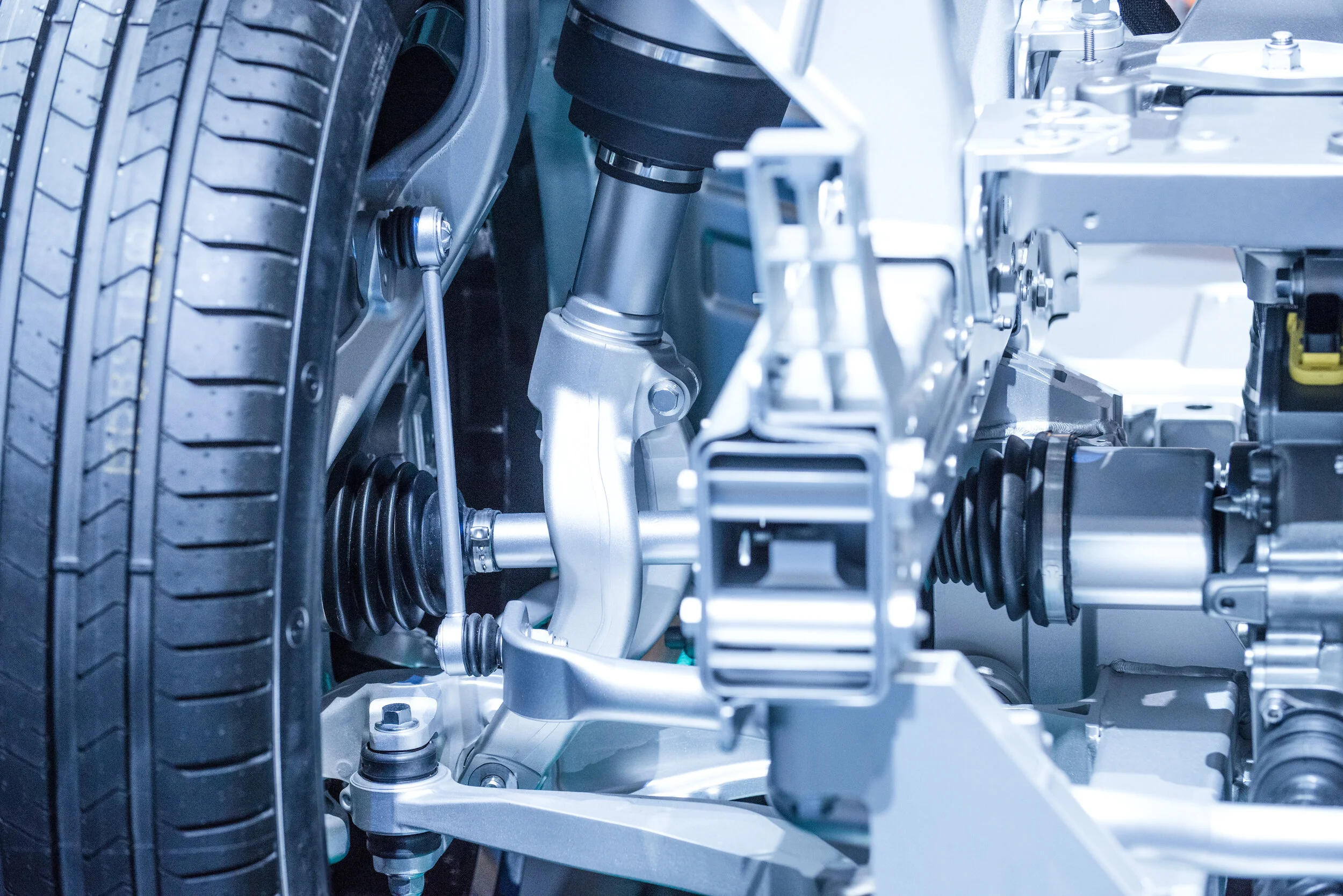

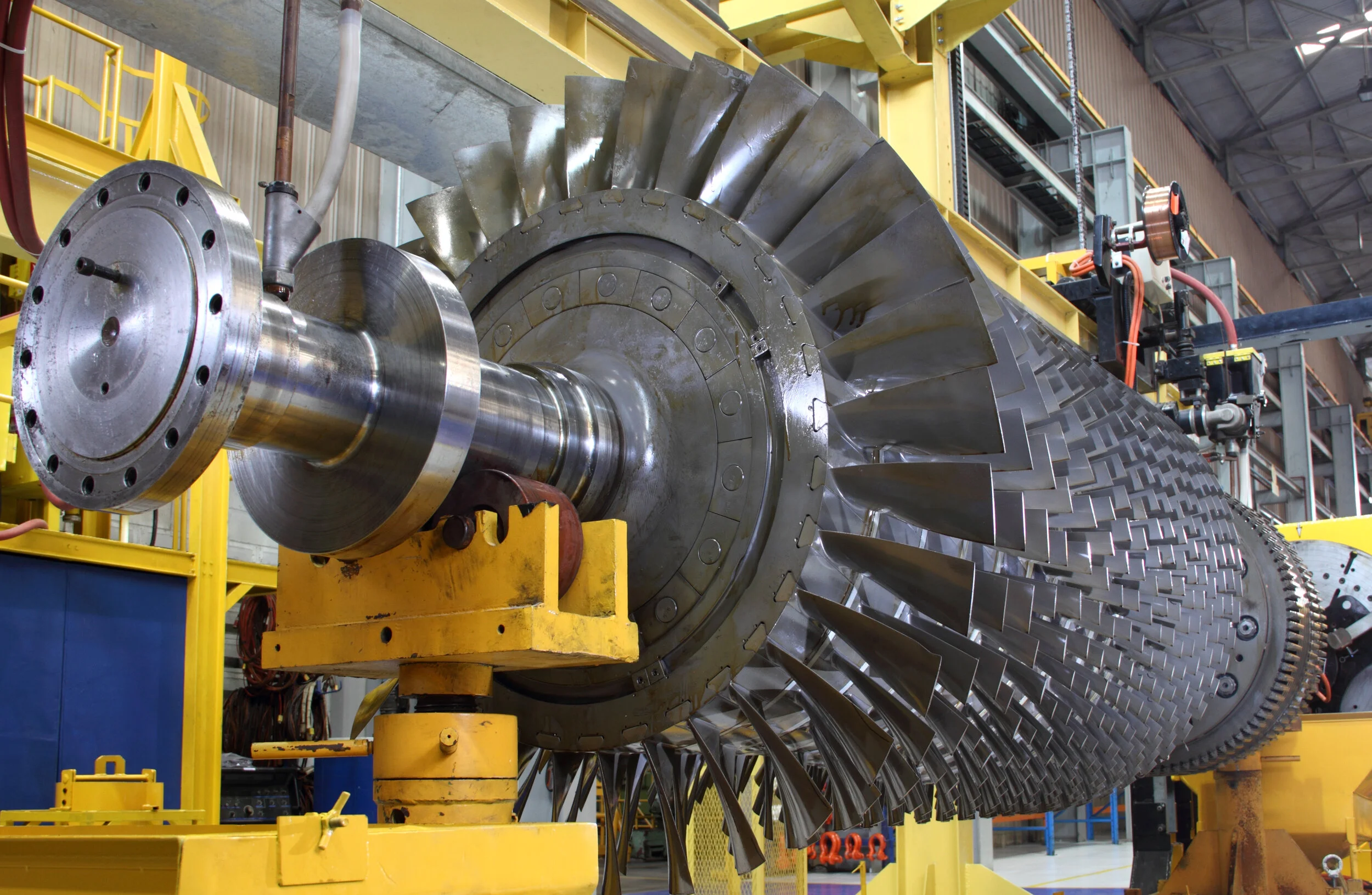

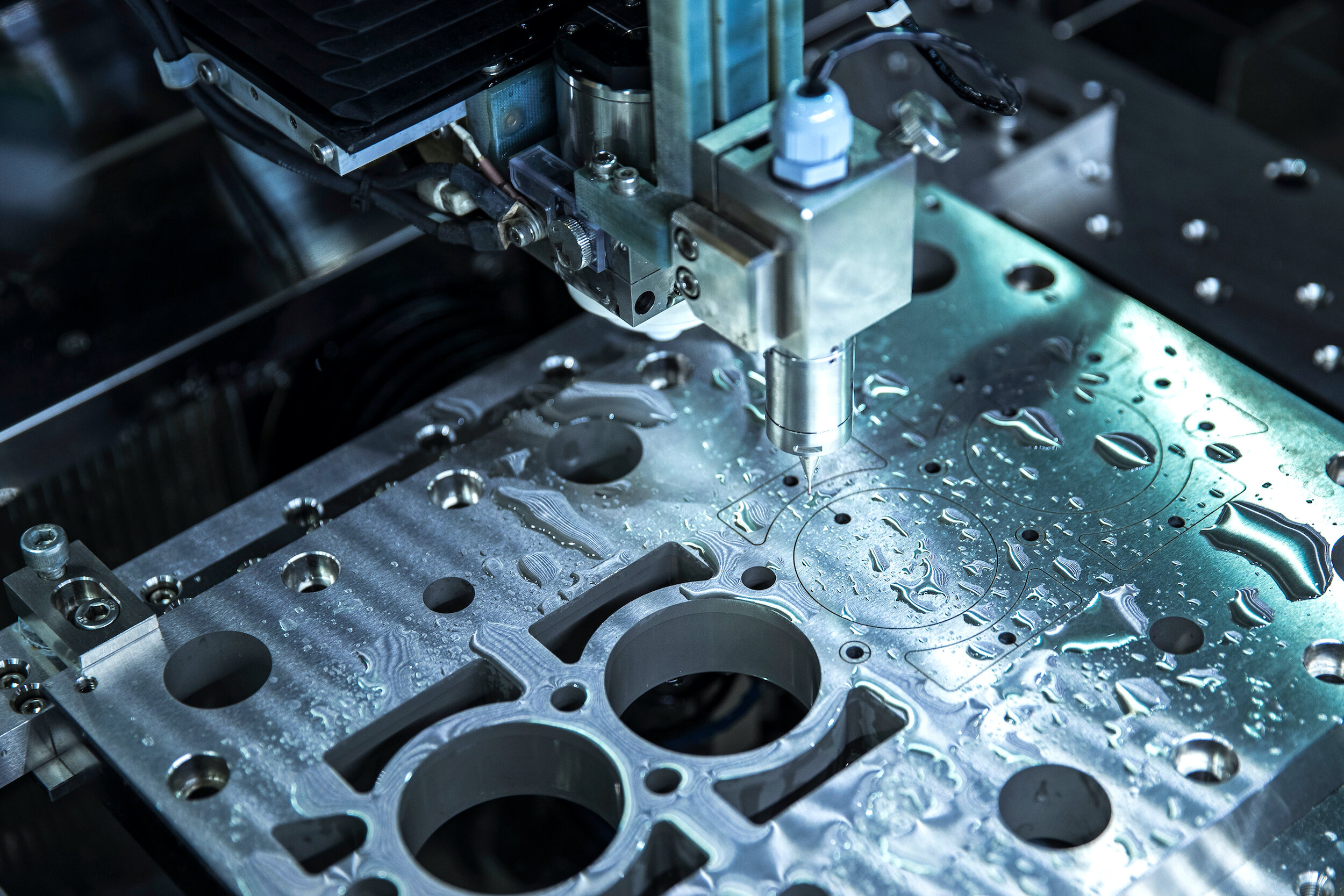

DDM Digital Foundry™ manufactures complex metal components for diverse industries using our DirectPour™ process. We take your part’s CAD model, then engineer and produce optimized, “ready to pour” ceramic shells without any tooling or patterns using advanced 3D printing. These shells are poured using the investment casting method with unprecedented speed and precision. We can help you adapt your designs to our advanced manufacturing methods and realize your complex designs, both for prototyping and series production in hundreds of standard alloys. Contact us today for more info.